一、產(chǎn)品用途

數(shù)控液壓板材沖孔機(jī)主要用于電力、通訊、汽車、鋼結(jié)構(gòu)等行業(yè)的金屬板材的沖孔及打鋼印作業(yè)。

二、產(chǎn)品特點(diǎn)

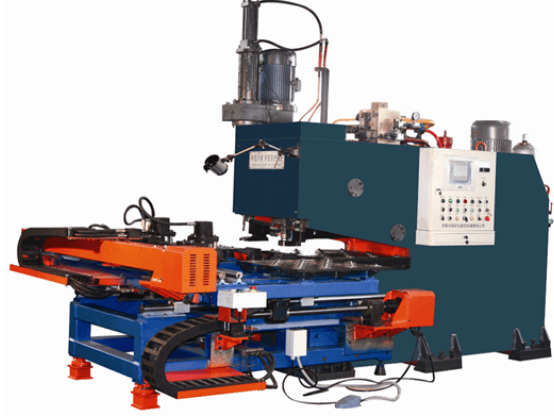

數(shù)控液壓板材沖孔打字機(jī)主要由兩軸數(shù)控工作臺(tái)及沖孔單元(主機(jī))組成。該機(jī)機(jī)身采用框架式鋼板焊接機(jī)身,設(shè)備剛性好,工作穩(wěn)定,換模采用了墊塊氣缸方式,換模準(zhǔn)確可靠。液壓、氣動(dòng)、電氣主要元器件均采用國際品牌,更加提高了設(shè)備的使用可靠性。

1、PLC控制,伺服電機(jī)送進(jìn);

2、機(jī)、電、氣、液一體化;

3、具有故障自我診斷功能;

4、編程簡易且可以直接使用放樣軟件所生成的程序數(shù)據(jù);

5、兼容最新道亨放樣軟件;

6、X軸及Y軸運(yùn)行由伺服電機(jī)+滾珠絲杠+精密直線導(dǎo)軌驅(qū)動(dòng),由雙軸數(shù)控系統(tǒng)控制沖孔位置。

7、整個(gè)加工過程自動(dòng)進(jìn)行,操作者把工件圖紙輸入計(jì)算機(jī),以后可以反復(fù)調(diào)用。

三、主要技術(shù)參數(shù)

1、最大沖孔壓力: 1000KN。

2、最大板材尺寸: 1500×800mm。

3、板材厚度: 5~25mm。

4、最大沖孔直徑:圓孔φ25.5mm(16Mn,20mm厚,Q235,25mm厚)。

5、沖孔速度:40-45次/min。

6、模位數(shù):3個(gè)(其中一個(gè)為打鋼印模位)。

7、最大打字力:800kN。

8、字頭數(shù)目及尺寸:10個(gè)(14×10mm)。

9、加工精度:符合GB/T2694標(biāo)準(zhǔn)。

10、液壓泵電機(jī)功率:15KW。

11、X,Y軸伺服電機(jī)功率:2×2KW。

12、所需壓縮空氣壓力×排量:0.5MPa×0.1m2/min。

13、潤滑方式:配備自動(dòng)潤滑。

First, product use

CNC hydraulic sheet punching machine is mainly used for punching and stamping of sheet metal in electric power, communication, automobile, steel structure and other industries.

Second, product features

The CNC hydraulic sheet punching typewriter is mainly composed of a two-axis numerical control worktable and a punching unit (host). The fuselage of the machine adopts frame type steel plate to weld the fuselage. The equipment has good rigidity and stable work. The die change adopts the block cylinder method, and the die change is accurate and reliable. The main components of hydraulic, pneumatic and electrical products are all international brands, which further improves the reliability of the equipment.

1.PLC control, servo motor feed;

2.Machine, electricity, gas and liquid integration;

3.With fault self-diagnosis function;

4.Easy programming and direct use of program data generated by the lofting software;

5.Compatible with the latest Dao Heng lofting software;

6.The X-axis and Y-axis are driven by the servo motor + ball screw + precision linear guide, and the punching position is controlled by the two-axis CNC system.

7.The entire machining process is carried out automatically, and the operator inputs the workpiece drawing into the computer and can be called repeatedly later.

Third, the main technical parameters

1. Maximum punching pressure: 1000KN.

2, the largest plate size: 1500 × 800mm.

3, sheet thickness: 5 ~ 25mm.

4, the largest punching diameter: round hole φ25.5mm (16Mn, 20mm thick, Q235, 25mm thick).

5. Punching speed: 40-45 times/min.

6, the number of modules: 3 (one of which is the stamping position).

7, the largest typing force: 800kN.

8. Number and size of the prefix: 10 (14 × 10mm).

9, processing accuracy: in line with GB/T2694 standard.

10, hydraulic pump motor power: 15KW.

11, X, Y axis servo motor power: 2 × 2KW.

12. Required compressed air pressure × displacement: 0.5 MPa × 0.1 m 2 / min.

13. Lubrication method: equipped with automatic lubrication.