一、適用范圍

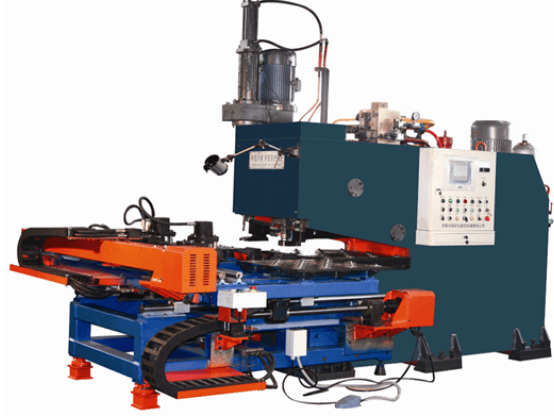

該機(jī)為電力電訊角鋼塔進(jìn)行角鋼打字、沖孔、剪切、全自動化生產(chǎn)的專用設(shè)備。適用角鋼型號在L40х3~L200х20,其長度在12米之內(nèi)的打字、沖孔、剪切的全部作業(yè)范圍。

二、結(jié)構(gòu)及性能

該機(jī)由六大部分組成:上料部分、送料部分、主機(jī)部分、成品下料部分、液壓動力部分、電器控制部分。

三、產(chǎn)品優(yōu)勢

A、設(shè)備鋼性強(qiáng),結(jié)構(gòu)緊湊;

B、 打字、沖孔、切斷、分選堆垛均自動進(jìn)行,生產(chǎn)效率高;

C、編程時只需鍵入工件的尺寸、孔徑、準(zhǔn)距、工件數(shù),也可以與設(shè)計部門構(gòu)成局域網(wǎng),共享數(shù)據(jù)資源;

D、采取了多項措施來解決角鋼彎曲引起的進(jìn)料困難和準(zhǔn)距誤差;

E、 優(yōu)化排料工序,材料利用率高;

F、 減輕工人勞動強(qiáng)度,保證工件精度穩(wěn)定。

四、技術(shù)特征

A、機(jī)、電、氣、液一體化;

B、計算機(jī)控制,伺服電機(jī)送進(jìn);

C、準(zhǔn)距任意設(shè)定,沖孔排數(shù)不限;

D、編程簡易且可以直接使用放樣軟件所生成的程序數(shù)據(jù);

E、 加工零件圖形顯示;

F、 角鋼彎曲較大時也能適應(yīng);

G、主要電氣部分與液壓、氣動元件均采用進(jìn)口產(chǎn)品。

First, the scope of application

This machine is a special equipment for angle steel typing, punching, shearing and fully automated production of electric power angle steel tower. Applicable angle steel model in L40х3 ~ L200х20, its length within 12 meters of the entire range of typing, punching, shearing.

Second, structure and performance

The machine consists of six parts: the feeding part, the feeding part, the main part, the finished part, the hydraulic power part and the electric appliance control part.

Third, product advantages

A. The equipment is strong in steel and compact in structure;

B. Typing, punching, cutting, sorting and stacking are all carried out automatically, and the production efficiency is high;

C. When programming, you only need to input the size, aperture, quasi-distance, and number of workpieces of the workpiece. You can also form a local area network with the design department to share data resources.

D. A number of measures have been taken to solve the feeding difficulty and the standard deviation caused by the bending of the angle steel; E. Optimizing the discharging process and the material utilization rate is high;

F. Reduce the labor intensity of workers and ensure the accuracy of workpieces.

Fourth, technical characteristics

A, machine, electricity, gas, liquid integration;

B, computer control, servo motor feed;

C, the standard distance is arbitrarily set, and the number of punching holes is not limited;

D, programming is simple and can directly use the program data generated by the lofting software;

E, graphic display of processed parts;

F. The angle steel can also adapt when it is bent.

G. The main electrical parts and hydraulic and pneumatic components are all imported products.

五、主要技術(shù)規(guī)格(Main technical specifications)